ETA

Overview

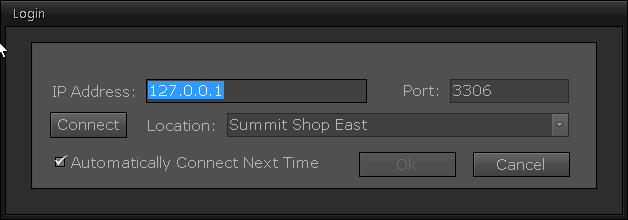

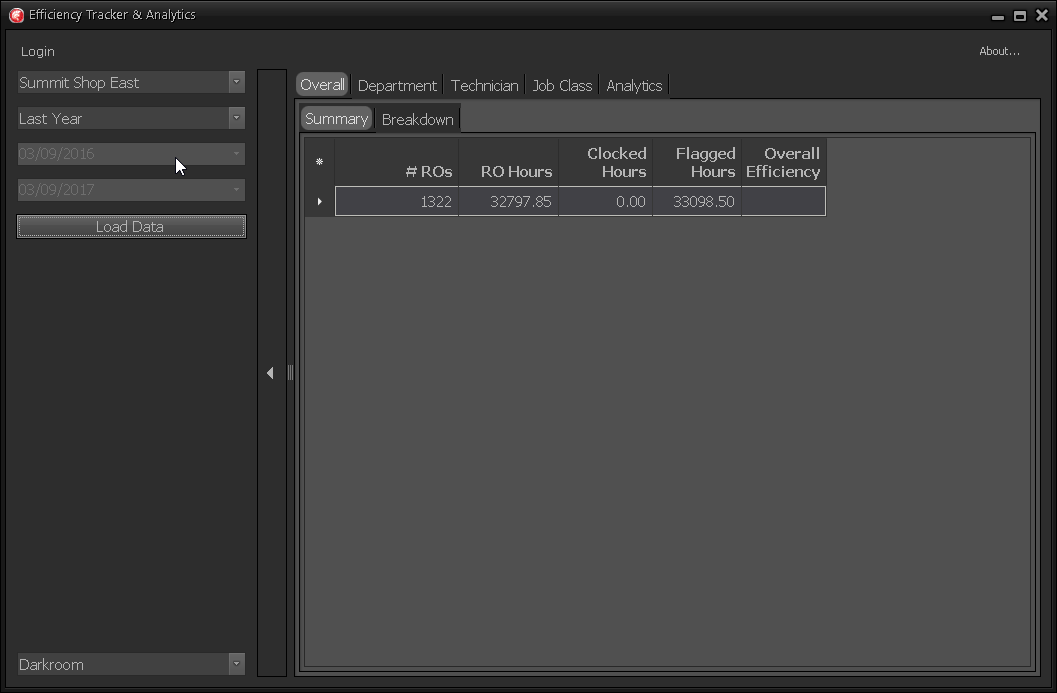

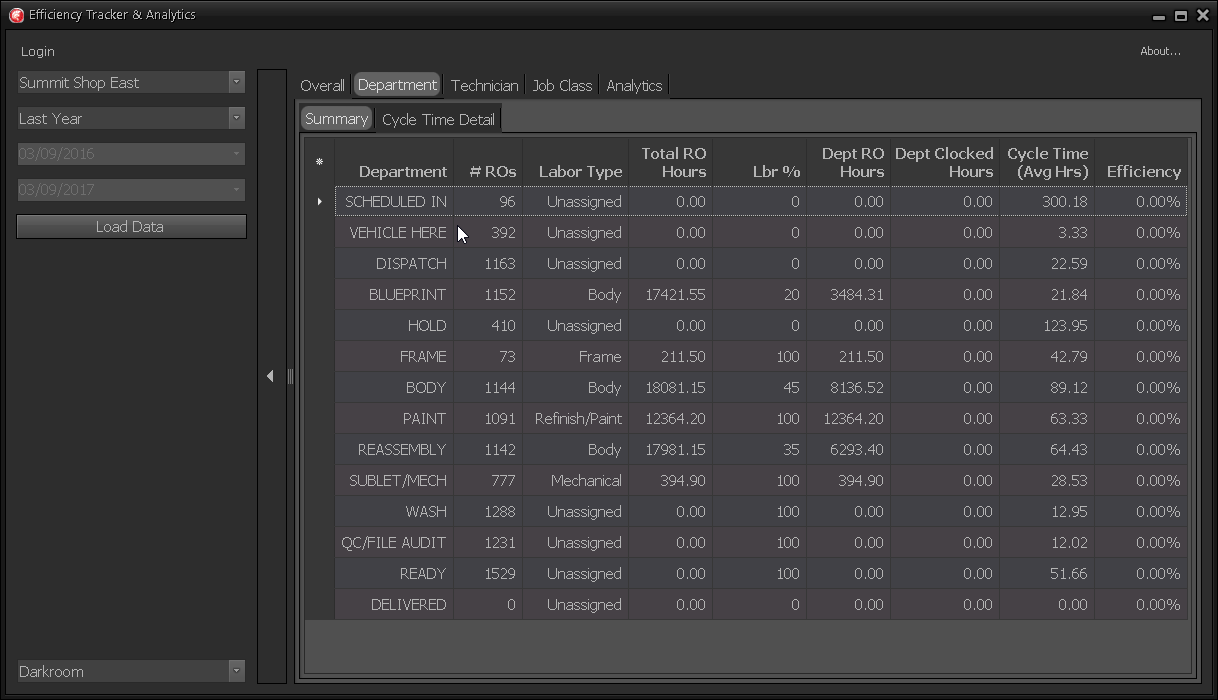

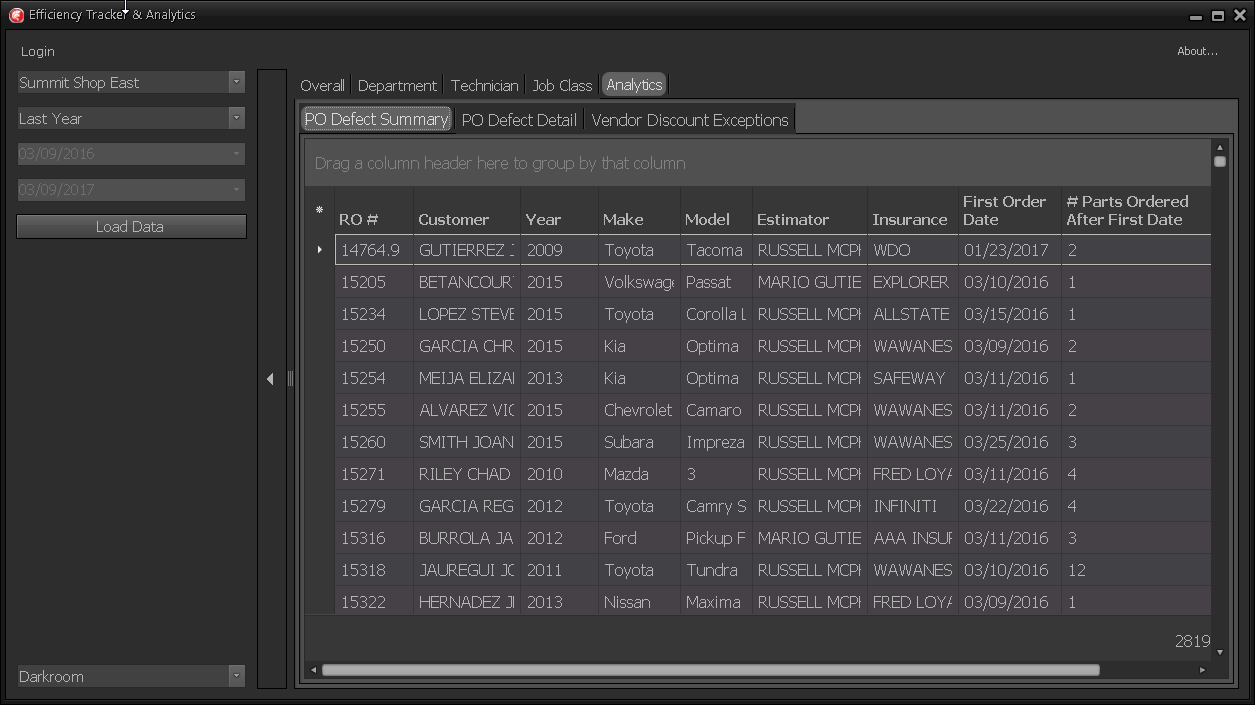

ETA, Efficiency Tracking and Analysis, is a tool designed for Produciton Managers, Shop Owners & GM's to see their efficencys at a Overall, Department, Technician, Jobclass level. For accurate tracking it is important that you are flagging your labor as well as having your technicians clock in via Tech Central or SuMo.

Below is all pdf documentation on ETA for Summit 8 Users, if you require additional assitance please contact SummitCRS Support at 1-800-789-9112 or 208-947-1738.

Frequently Asked Questions

ETA is only as good as the data we give it, therefor if we have inconsistent clocking and flagging of labor to techs then our data will reflect that. Typically by looking at the data we can figure out where the problem is, i.e. if the RO/Flagged labor hours are drastically lower than clocked hours is indicitive of incorrect labor flagging. The reverse is also true where Flagged Labor hours are high and clocked hours are very low this would indicate we are not clocking into RO's with Tech Central or SuMo.

If you're a shop that doesn't flag labor but does record time clock RO punches you may want to check out Tech Metrix which calculates a cost based efficiency based on timeclock punches.

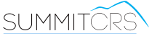

First verify you have the correct IP address for your Summit Server, then verify the port. If this information is correct is this workstaion connected to the shop network the server is on? If not you will need to add this machine to the network or utilize the external ip address for the server while making appropraite port forwarding and firewall settings.

If you are seeing 0.0 values for these fileds this is because you are a SummitCRS Ascent subscriber and do not posses the nessesary components in the software to collect data for these values. You can upgrade to the full SummitCRS software suite or add Summit Mobile (SuMo) to collect this data.

This error is indicitive of a few different things. First, you will want to check your server ip and port as they are set up in the login screen. Verifiy your IP & Port by clicking on the location link on the login screen of any functioning SummitCRS client software. Should the error still persist next would be to make sure the paint scale machine is on the same network as the rest of the shop and has necessary permissions to access the server.

ETA is designed for a single server set up, when the program opens up it will prompt for your Server IP and port, once this information is added simply hit connect and ETA should do the rest.